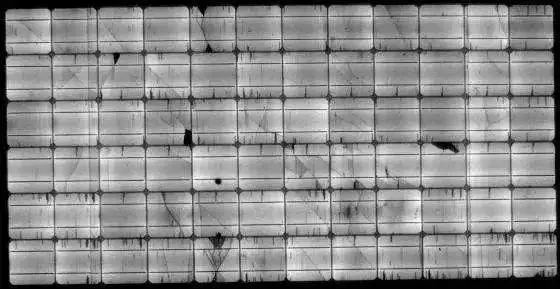

The solar module EL defect detector detects cracks, fragments, solder joints, disconnections, and abnormalities in solar cell modules with different conversion efficiency. There are monocrystalline silicon and polycrystalline silicon solar cells, but due to the randomness of manufacturing conditions during the production process, there are some defects in the production process. The EL detector uses infrared testing method to test battery components, achieving EL imaging mode, and detecting whether there are defects such as battery breakage, cracking, black chips, severe disconnection, solder breakage, solder breakage, and solder breakage inside the battery components. Then we move on to the next process, as the light emitted by the power supply is closely related to the ion concentration in the PN junction. Therefore, based on the image reflected by the EL computer, we can determine whether the inside of the silicon wafer is abnormal. This ensures the quality of solar cell components.

So what are the drawbacks of solar cells?

Black heart film: The main reason for the formation of black heart film reflected in EL photos is that the area does not emit 1150 infrared light, causing the black heart film to reflect in infrared photos. This black core board is formed due to the high electrical resistivity in the central part. It is related to the minority carrier concentration of the silicon substrate.

Black film: In the production process, due to repeated emphasis on the shortened Directional solidification time crystal, the latent heat release melting and temperature gradient of the temperature field do not match, the crystal growth rate is accelerated, and the internal dislocation silicon wafer caused by excessive thermal stress.

Short circuit black chip: a short circuit caused by a single wire welding component; Short circuit black film formed by low battery efficiency before component lamination; A black film with bright edges is called a non short-circuit black film. Mainly due to the incorrect use of n-type chips in silicon wafers, the PN junction and short-circuit battery cannot provide external power, and the output power and IV test curve are also reduced. This affects the overall component power and filling factor.

Battery grid: The battery grid is caused by improper parameter settings or unqualified screen printing quality during the screen printing process of solar cells. A slight gate break is not very important for the component, but if the gate is severe, affecting the current of a single cell will affect the electrical performance of the entire component.

Cracks: There are many factors that contribute to the formation of battery cracks. It may be various external factors, or cracks or even fragments caused by environmental and battery defects. Therefore, it is difficult to find a unified law or obtain a clear answer. The imaging feature of the crack film is the line (black line) that produces a significant difference in light and dark during the EL test. The possible consequence of battery rupture is partial damage or loss of current.

From the above analysis, it can be seen that the automatic EL defect detector can quickly and accurately detect defects such as cracks in solar cells and components through EL imaging. The EL defect detector adopts an imported cooled infrared camera, which captures clear and accurate images. The unique specular reflection design and closed optical path design effectively adapt to different working environments, and have fully functional PC software support to meet the different needs of customers.

keywords:

Chinese

Chinese

English

English

Chinese

Chinese

English

English