Welcome to Wuhan Yoha Solar Technology Co., Ltd!

common problem

Site Map

Language:

Chinese

Chinese

English

English

Welcome to Wuhan Yoha Solar Technology Co., Ltd!

common problem

Site Map

Language:

Chinese

Chinese

English

English

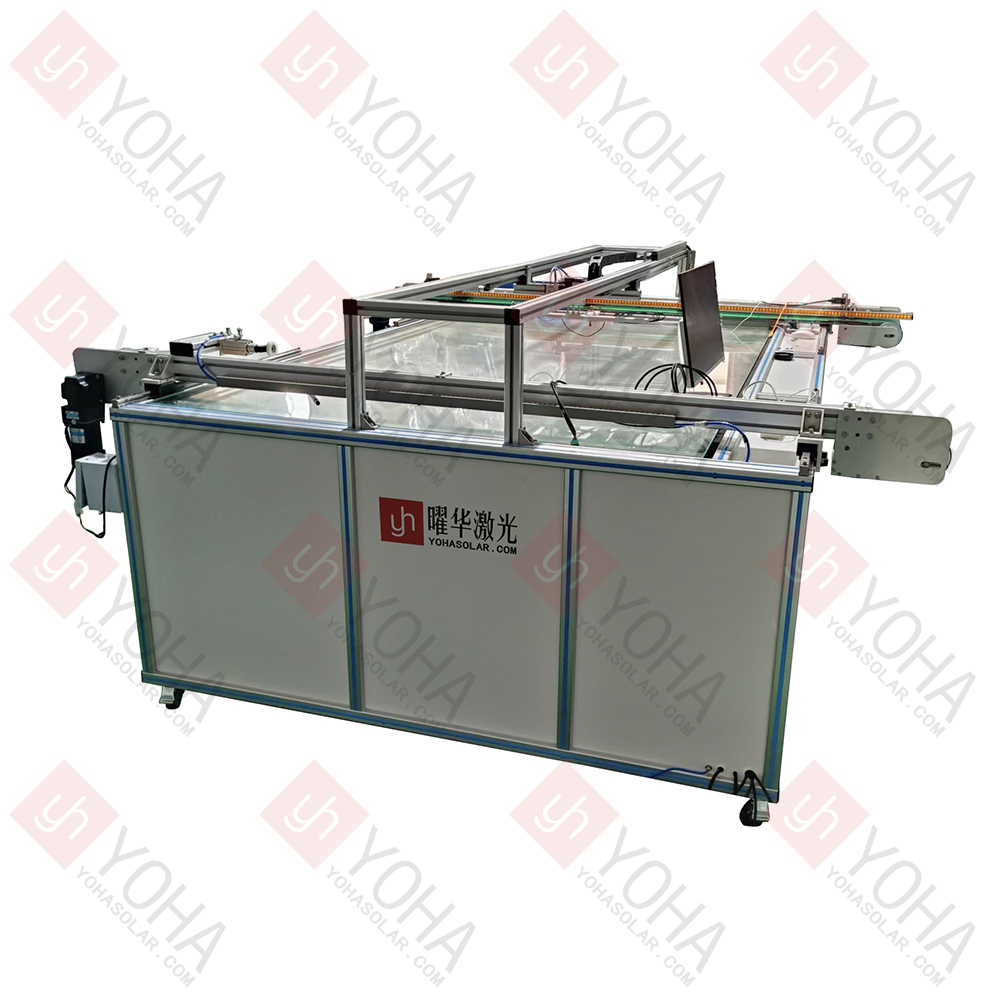

The Online Solar Module EL Defect Detector is a highly precise, automated, non-destructive testing device integrated into photovoltaic production lines. Utilizing the principle of Electroluminescence (EL), it automatically performs rapid imaging and real-time analysis on solar modules without manual handling. It accurately identifies various internal defects and process issues, including micro-cracks, finger interruptions, broken cells, black cores, sintering defects, and PID degradation.

| Item | Parameter |

|---|---|

| Model | YHEL-2400 |

| Applicable Process Stage | Defect detection for pre/post-lamination modules |

| Test Specification | Dual-glass monocrystalline, polycrystalline cell modules |

| Camera Type | Yaohua Specialized Camera |

| Resolution | EL: 24MP / 48MP |

| Imaging Mode | Single/Dual Camera Mode |

| Sensitivity | Detects cracks narrower than 0.03mm |

| Loading Method | Automatic Loading/Unloading |

| Detection Method | Automatic Detection |

| Effective Test Area | 2600*1500mm |

| Stabilized Power Supply | 60V/20A |

| Image Acquisition Time | 1~60s (Adjustable) |

| Power Supply | 220V/50HZ |

| Equipment Dimensions (LxWxH) | 2900×1940×1155mm |

1. Full-Process Quality Control in PV Module Production: Serving as a core quality inspection tool on the production line, it is applied at critical stages: incoming material (cell) inspection, post-soldering/layup, pre/post-lamination encapsulation, and final product outgoing inspection. By enabling real-time, non-destructive detection of internal defects, it strictly controls quality at each step, preventing defective products from moving downstream or reaching customers, significantly improving yield and product reliability.

2. PV Power Plant Module Receiving Inspection & Installation QC: During PV power plant construction, used for batch sampling or full inspection of received solar modules to verify if internal damage (e.g., micro-cracks) occurred during transportation or handling. It can also be used for re-inspection after modules are mounted on racks (installation stress testing) to ensure the installation process caused no damage, laying a quality foundation for long-term stable operation and preventing power loss or safety hazards due to latent defects.

3. PV Power Plant O&M Fault Diagnosis & Performance Assessment: As a vital diagnostic tool for plant operation and maintenance, used for periodic inspections or troubleshooting. When abnormal performance degradation (e.g., reduced output, hot spots) is detected, EL testing quickly and visually locates internal defects (e.g., severe micro-cracks, broken cells, PID effect, cell failure, soldering failure), accurately determining the cause and severity to guide repair or replacement decisions, maximizing power generation revenue and asset value.

4. R&D and Process Improvement Support: In PV module/cell R&D labs and process improvement departments, the EL detector is a key device for evaluating the reliability of new materials, structures, and processes (e.g., novel cell technologies, different soldering/encapsulation methods). By comparatively analyzing EL images under various conditions, it enables in-depth research into defect formation mechanisms, distribution patterns, and performance impacts, providing strong data support for continuously enhancing module design, optimizing manufacturing processes, and improving product lifespan.

1. Strict Electrical Safety Operation: The device involves applying current to modules to induce luminescence. Strict adherence to electrical safety regulations is mandatory. Operators must wear insulated gloves, ensure correct and secure module wiring to avoid short circuits or electric shock. Always disconnect power before subsequent operations (e.g., moving modules). Testing is strictly prohibited in humid environments or if the module has visible damage.

2. Ensure Darkroom Light-Tightness: EL imaging is highly sensitive to ambient light. Testing must be conducted in a completely light-tight darkroom or dark box. Before testing, carefully check the sealing of doors, observation windows, cable entries, etc., to eliminate any external light interference (including indicator lights, screen glow). Failure to do so will severely degrade image quality, leading to missed defects or false positives.

3. Standardized Operation and Equipment Protection: Handle modules gently during placement to avoid causing new micro-cracks or damage. Exercise extreme caution when operating the high-sensitivity infrared camera to prevent lens impact. Operate strictly according to the manual, avoiding overloads or incorrect parameter settings (e.g., current level, exposure time). Keep equipment clean, especially the camera lens and loading platform.

4. Thorough Pre-Test Preparation: Ensure the module is at room temperature (avoid extreme temperatures affecting luminescence). Check that the module surface is clean, dry, and free of large stains or water droplets obstructing the view. Precisely set test parameters (e.g., applied current, voltage range) based on module specifications (power, current characteristics). Improper parameters can cause overexposure, underexposure, or failure to effectively reveal defects.

5. Emphasize Image Interpretation and Software Maintenance: Interpreting EL images requires expertise and experience. Operators must be trained to recognize characteristic features of different defects (e.g., crack patterns, shapes of black cores, linear finger interruptions) and distinguish real defects from image artifacts (e.g., noise, interference patterns). Regularly calibrate the device and update the image analysis software to ensure the detection algorithms and defect recognition database are current, improving judgment accuracy.

6. Regular Maintenance and Professional Servicing: Establish and execute a regular equipment maintenance schedule. This includes cleaning optical components (lenses, filters), checking electrical connection reliability, and calibrating light sources and camera parameters. For in-depth maintenance or repair of critical components (e.g., IR camera, power modules), engage the equipment supplier or qualified technicians to avoid damage or performance degradation from self-disassembly.

TOP

18086473422

MESSAGE