Welcome to Wuhan Yoha Solar Technology Co., Ltd!

common problem

Site Map

Language:

Chinese

Chinese

English

English

Welcome to Wuhan Yoha Solar Technology Co., Ltd!

common problem

Site Map

Language:

Chinese

Chinese

English

English

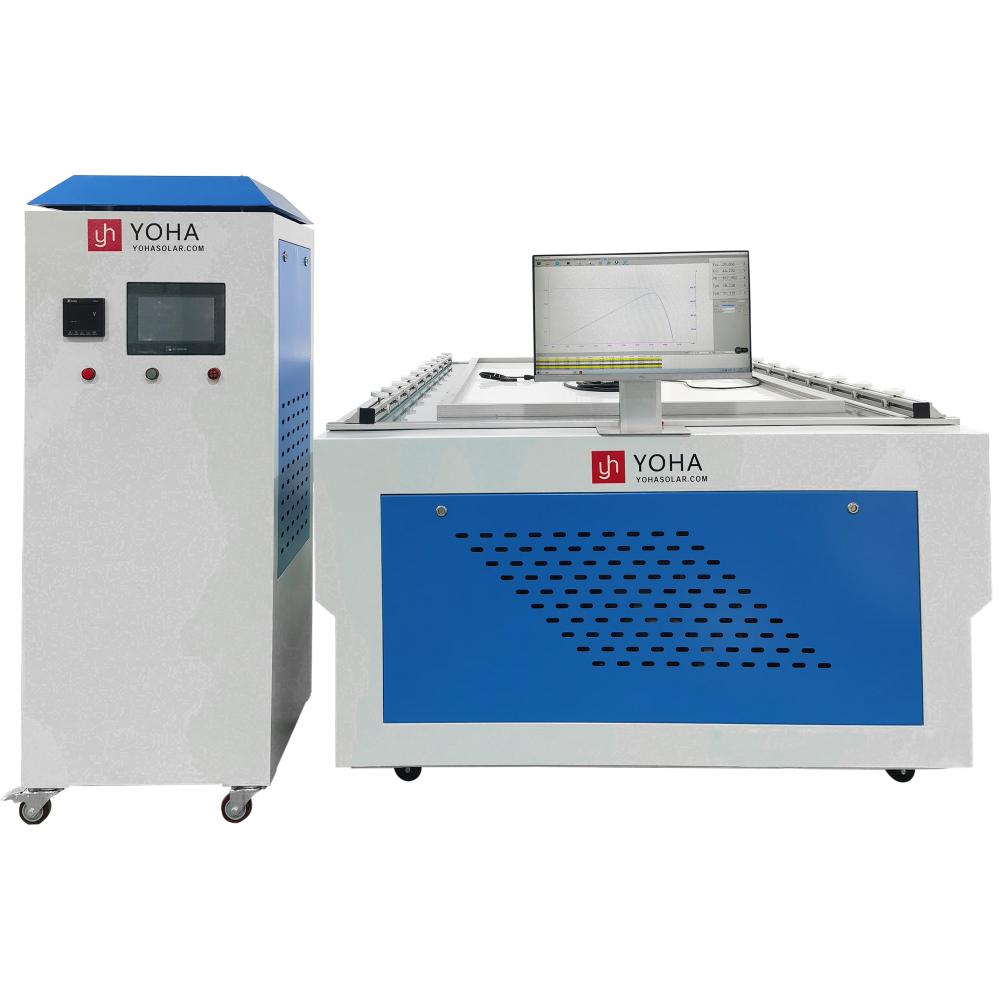

The IV curve testing of photovoltaic modules is a key technology for evaluating their performance. By measuring the current voltage (I-V) characteristic curve, the working state of the component under different lighting conditions can be comprehensively understood, including key parameters such as efficiency, maximum power point, volt ampere characteristics, and impedance characteristics. A solar simulator is a device that can accurately replicate the spectral characteristics of the sun and is widely used in IV testing of photovoltaic modules. The following will provide a detailed introduction to the role and importance of solar simulators in photovoltaic module IV testing.

1. Basic principles of IV curve testing

The I-V curve of PV modules reflects their corresponding current characteristics at different voltages. By measuring this curve, the working efficiency and performance parameters of the components can be extracted. The shape of the IV curve is determined by multiple factors, including light intensity, temperature, material properties, and component structure. A solar simulator provides controllable light source conditions, typically including adjustable light intensity (irradiance) and spectral distribution. By changing these parameters, the I-V characteristics of the component can be tested under different lighting conditions.

2. The role of solar simulator

Accurate simulation of actual lighting: Standard white light simulators cannot fully reproduce the actual distribution of the solar spectrum (such as the AM1.5G standard spectrum), while professional solar simulators can accurately control light intensity, wavelength, and direction, thus closer to real solar radiation conditions.

Multi condition testing: The simulator can simulate lighting environments under different weather conditions, such as sunny, cloudy, indoor simulation, etc., by adjusting parameters such as light intensity and wavelength. This helps to comprehensively evaluate the performance of components in various practical work scenarios.

High precision measurement: Modern solar simulators typically integrate high-precision light sources and detection equipment to ensure accurate measurement of current and voltage, thereby improving the reliability of test results.

3. Application scenarios for IV testing

Efficiency evaluation: By measuring the I-V curve of the component under different lighting conditions, the working efficiency of the component can be determined. High efficiency components are typically able to output more electrical energy at lower light intensities and have higher commercial value.

Fault diagnosis: Analyzing abnormal points in the I-V curve (such as the lowest voltage point where the current is zero) can help identify defects or causes of faults in components, such as short circuits, open circuits, local shadows, etc.

Material performance research: Solar simulators can be used to study the effects of different materials or structures on the performance of photovoltaic modules. By comparing the I-V curves of different components under the same lighting conditions, the effectiveness of material optimization schemes can be evaluated.

4. Actual case analysis

Taking common monocrystalline silicon photovoltaic modules as an example, when using a solar simulator in IV testing, it is usually tested under standard lighting conditions (such as AM1.5G). The specific steps are as follows:

1. Light source setting: Adjust the solar simulator to the appropriate light intensity and wavelength range.

2. Component connection: Connect the photovoltaic module to the testing instrument (such as a multi parameter data acquisition system) to ensure measurement accuracy and stability.

3. Data collection and analysis: Adjust the lighting conditions through a simulator and collect real-time current and voltage data of the components. Use software to analyze data and extract key performance parameters.

5. Summary

The application of solar simulator in photovoltaic module IV testing is a key technology to ensure accurate and comprehensive test results. It can simulate the performance of components under various actual lighting conditions, providing reliable data support for component design, optimization, manufacturing, and quality control. With the rapid development of solar energy technology, the demand for efficient and accurate IV testing equipment will continue to increase. In the future, with the continuous advancement of solar simulator technology, its application in photovoltaic module testing will be more extensive and accurate, further promoting the development of global clean energy.

keywords:TOP

18086473422

MESSAGE