Welcome to Wuhan Yoha Solar Technology Co., Ltd!

common problem

Site Map

Language:

Chinese

Chinese

English

English

Welcome to Wuhan Yoha Solar Technology Co., Ltd!

common problem

Site Map

Language:

Chinese

Chinese

English

English

The production process of photovoltaic modules is the process of integrating and assembling components such as solar cells, photovoltaic glass, and EVA. Quality control at every stage of this process is crucial and directly related to the performance and service life of the product. This article will provide a detailed introduction to the key testing steps and their importance in the packaging production of photovoltaic cell modules.

1、 Key checkpoints in the encapsulation process

1. Electrical characteristic testing

Electrical characteristic testing is one of the most important inspections in the packaging process. It mainly includes the following contents:

Current output test: Measure the current value of a single chip or component to ensure that it meets the design requirements.

Voltage output test: Measure the voltage value to ensure that it reaches the expected level under rated operating conditions.

Power matching test: Verify the power matching between components by measuring the current voltage curve under lighting conditions.

2. Optical performance testing

Optical performance is an important indicator for measuring the efficiency of photovoltaic cell modules. The main testing contents include:

Light intensity test: Measure the output power of the component under standard lighting conditions to ensure compliance with specifications.

Power output test: Verify the stability and adjustability of the components by adjusting the light intensity.

3. Appearance inspection

Visual inspection is an important step in ensuring the integrity and quality of components. Including the following content:

Dimensional inspection: Measure whether the dimensions of the components meet the design requirements.

Surface quality inspection: Check for scratches, bubbles, and other defects on the photovoltaic cells and brackets.

Contact resistance test: By checking the contact condition at the electrical connection, ensure good connection between components.

4. Environmental durability testing

In practical application environments, components may be affected by various factors such as temperature fluctuations and humidity changes. Therefore, the following durability tests are also required in the packaging process:

High temperature aging test: simulating long-term stability testing under high temperature environment.

Low temperature cycling test: Verify the performance stability and reliability of components in extreme low temperature environments.

2、 The Importance of Quality Inspection

1. Ensure product performance

Each stage of testing can effectively ensure that the electrical and optical performance of the components reach the expected level. Only through strict quality control can the photovoltaic system ensure stable and clean energy output.

2. Improve product reliability

Quality inspection can effectively detect and eliminate non-conforming components, reducing the possibility of product failure during use. This is crucial for improving the service life and reliability of the product.

3. Meet market demand

With the increasing global emphasis on new energy, consumers have higher requirements for the performance and quality of photovoltaic products. Through a rigorous testing process, we can provide products that meet the standards and demands of the market.

3、 Continuous improvement of quality inspection

The quality inspection process needs to be continuously optimized and improved to adapt to technological advancements and changes in market demand. Enterprises can improve their testing capabilities through the following methods:

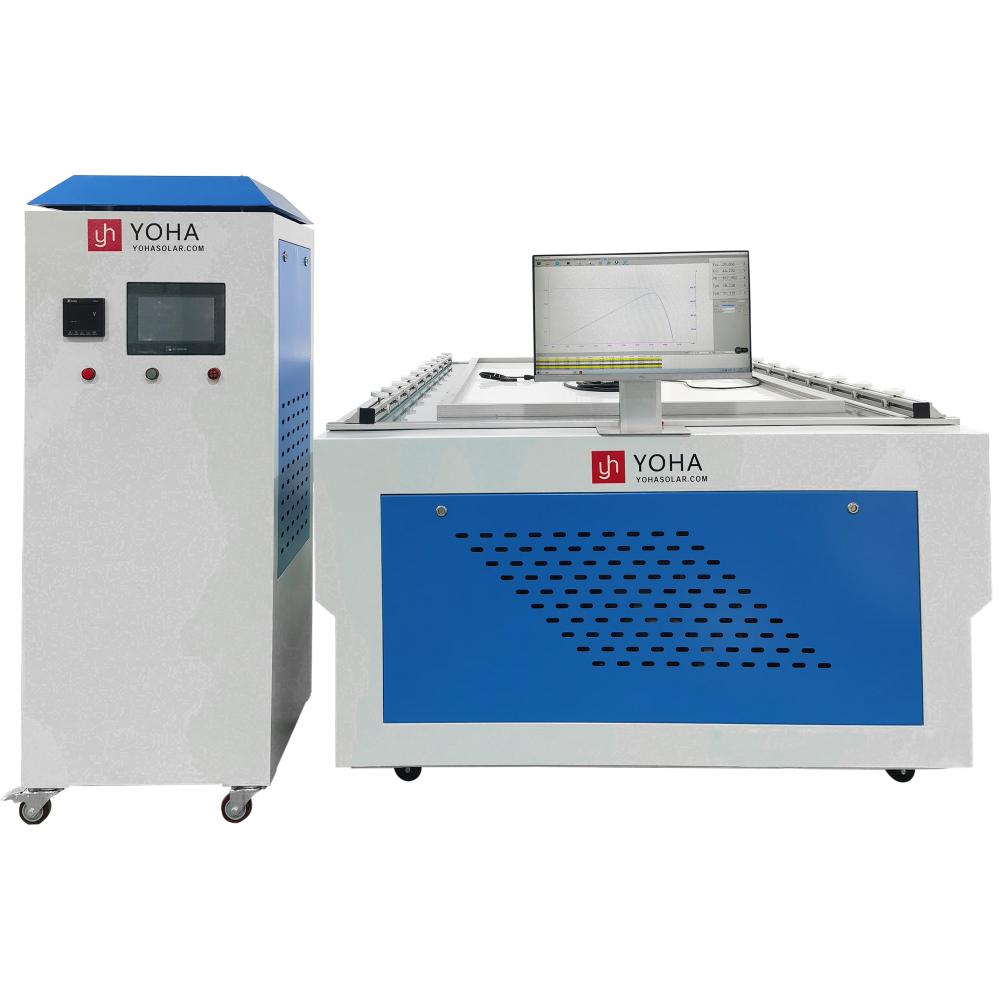

Introducing advanced detection equipment: using more precise detection instruments and technical means to improve the accuracy of test results.

Establish a strict quality management system: By developing detailed operating procedures and testing standards, ensure that every step is systematic and traceable.

Develop a quality traceability system: Record and analyze non-conforming components in detail, identify the root cause of the problem, and improve production processes.

In the production process of photovoltaic cell modules, strict testing procedures are required at every stage. Only through comprehensive quality control can the high performance and long lifespan of the product be ensured. Enterprises should continuously optimize their testing technology and strengthen employee training to achieve higher quality standards and service levels. Only in this way can we stand out in the fierce market competition and make greater contributions to the development of renewable energy worldwide.

keywords:TOP

18086473422

MESSAGE